Categorie

- Toys

- Welding Water Cooler

- Tungsten Electrode Grinder

- Portable Electrode Oven

- Industrial Electrode Oven

- Welding Positioner

- Welding Rotator

- Welding Manipulator

- Collaborative Robots / COBOTS

- MIG/MAG Welding Carriage

- TIG Welding Wire Feeder

- Robotic Torch Cleaning Station

- Welding Fume Extractor

- 3D Flexiable Welding Tables

- Punch Machine

- Magnetic drill & Annular cutter

Browse History

Description

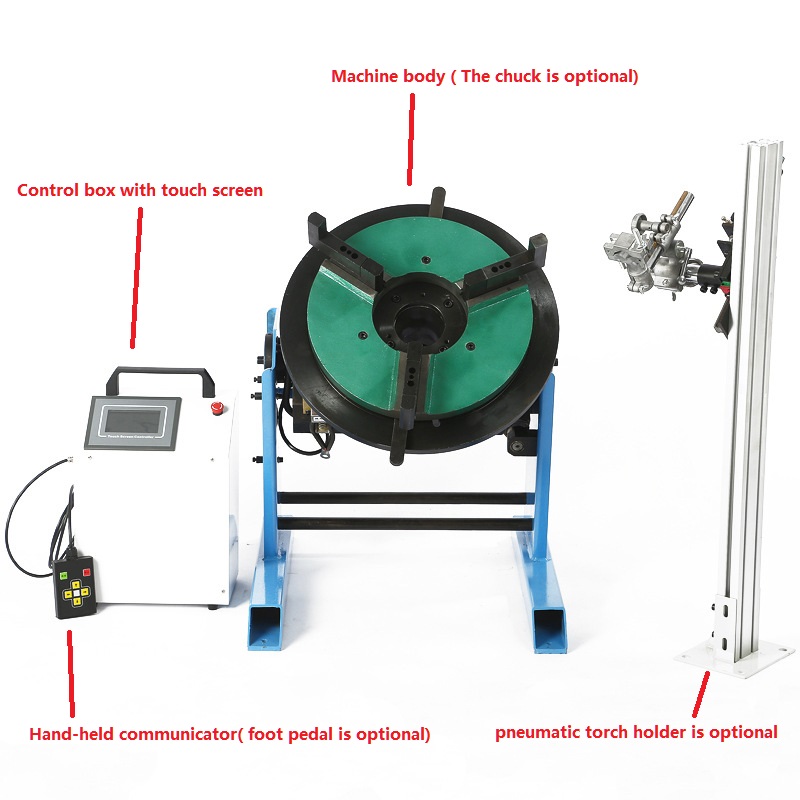

This positioner has functions such asautomatic rotation, starting and stopping of the welding torch, automatic lifting and lowering of the welding torch, and delaying the welding torch, and can be used for segment welding, full welding, spot welding, etc.;

Mainly through the inclination and rotation of the worktable, and fix the chuck or specific tooling on the worktable to clamp the workpiece, so that the workpiece can be accurately positioned and placed in the best welding position to ensure the welding quality.

Key Features

●PLC control, touch screen panel。

●It can automatically start/stop the arcwhen it is linked with the welding machine, and can be connected with the welding oscillator to work synchronously。

●The CNC Series welding positioner is self-developed as one high-end positioner, which is driven by high-accuracy step motor with high precision, hightorque and detailed control program.

● therotation speed range is: 0.01r/min-9.00r/min ; rotation speed can be set upoptionally in measurement unerring;

● Rotation angle can be set upoptionally within 0-750°;

● Controller has the function ofmemory storge. and the parameter which has been set can be read for the nextoperation.

● Special design ofanti-electromagnetic, which reduces the high frequency.

● The machine can work togetherwith the welding robot for the precise welding. The linkage can be realizedthrough welding.

● The lagging time and arc starting can be set for welding. The lagging time can be set according to requirement while linkage with the welder.

● The machine responses quickly,starting and stopping very smoothly.

● The through-hole structure can facilitate the welding, which can delivery theprotective gas.

Packaging Including:

-Main Body: 1 Set;

-Control box: 1 piece;

-Hand-held communicator: 1 piece (Footpedal is optional);

-The Chuck is optional

Specification

| Model | NC-30 | NC-100 | NC-200 | NC-300 |

| Horizontal load | 30kg | 100kg | 200kg | 300kg |

| Vertical load | 15kg | 50kg | 100kg | 150kg |

| Rotation speed | 0.01-5.00rpm | 0.01-5.00rpm | 0.01-5.00rpm | 0.01-5.00rpm |

| Tilt (Degree) | 0°-90°/By Manual | 0°-90°/By Manual | 0°-90°/By Manual | 0°-90°/By Manual |

| Work table Dia. | 315mm | 400mm | 400mm | 500mm |

| Work table height | 400mm | 500mm | 500mm | 600mm |

| Center hole Dia. | 25/65mm | 45/80/140/170mm | 45/80/140/170mm | 90/170mm |

| Motor | 86 Stepper motor | 86 Stepper motor | 86 Stepper motor | 86 Stepper motor |

| Weight | 32kg | 85kg | 90kg | 130kg |

| Adapter chuck | KD-200/300 | KD-200/300/400 | KD-200/300/400 | KD-300/400/500 |

| Input voltage | 1PH 220V 50~60Hz | 1PH 220V 50~60Hz | 1PH 220V 50~60Hz | 1PH 220V 50~60Hz |

Remarks: The color, voltage, table rotate speed anddiameter , center hole diameter can be design according customers’ requirements.

How to assemble the welding postioner NC-30